Unlocking BMW's 'Joy Factor': How Software Will Revolutionize the Driving Experience

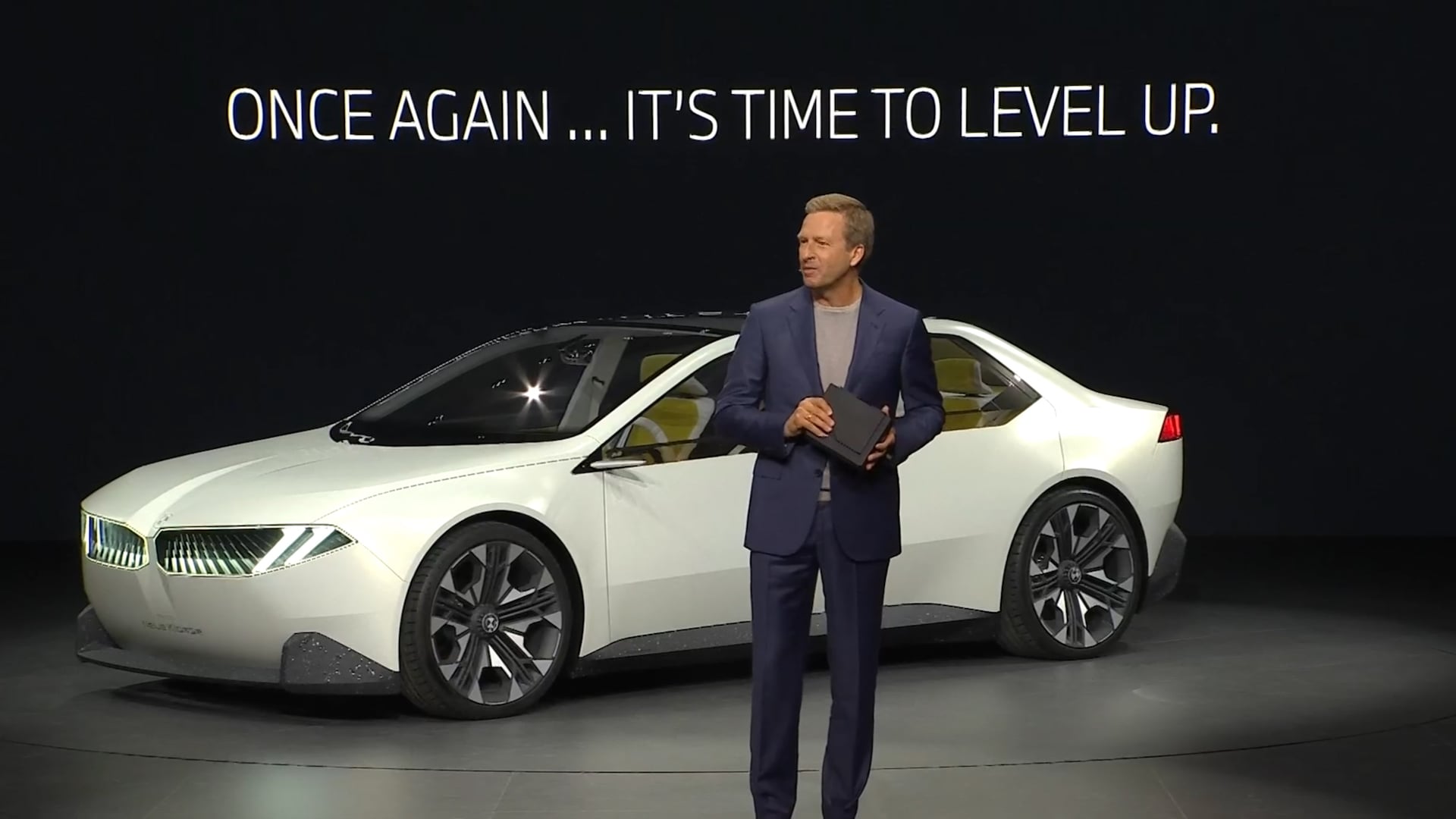

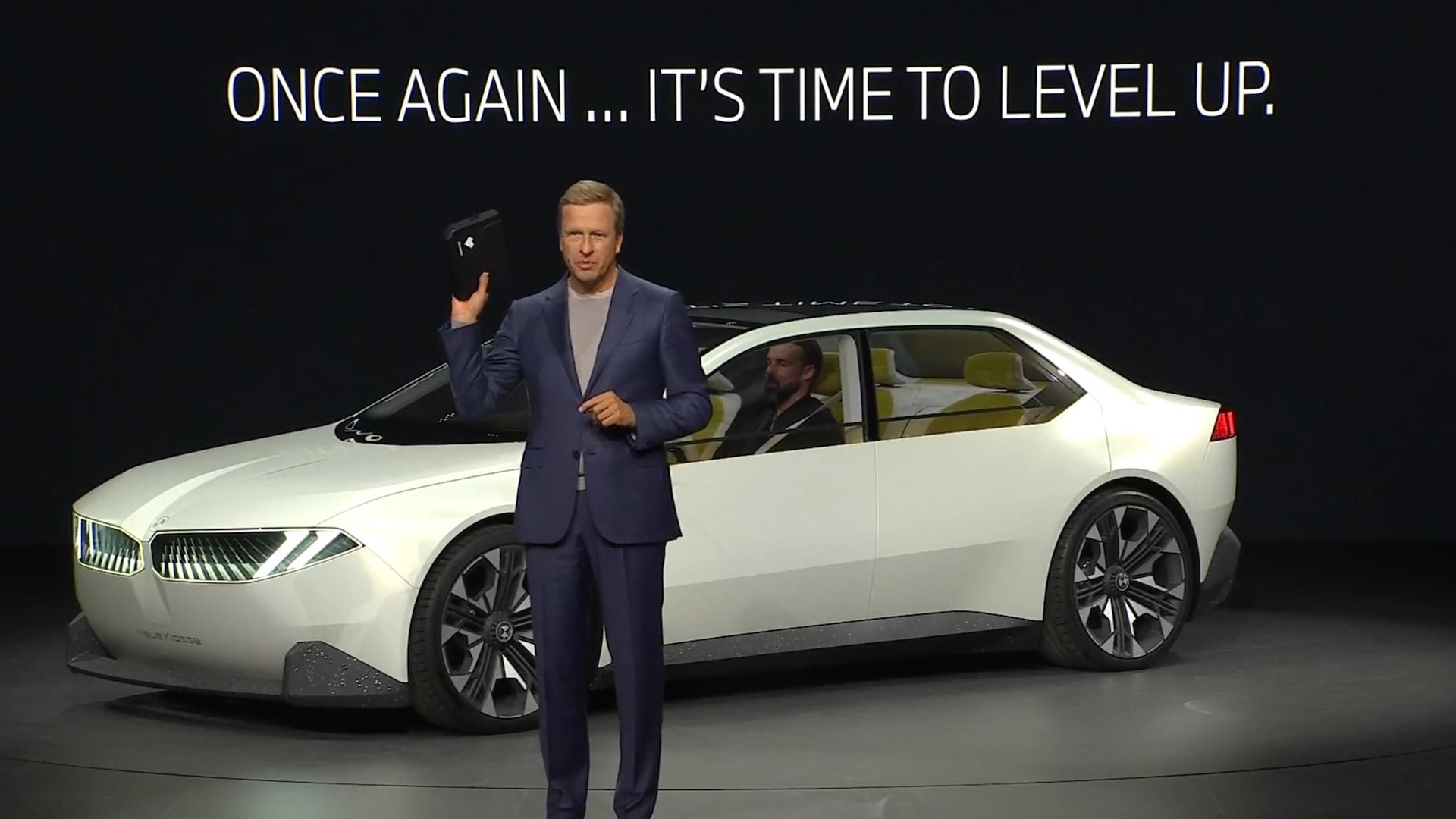

BMW is doubling down on code to "level up" its Neue Klasse cars.

Where does a car's character live? Is it in the suspension? The engine? Is it the way the seats squeeze your sides or the way the exhaust tickles your ears? In reality, a car's character is defined by all those things and more—or it was, at least. Now, with digital processors controlling everything from the torque turning the wheels to the dampers managing the suspension, the defining elements of a car's behavior have less to do with the hardware and more to do with software.

The code developed by programmers plays a crucial role; however, since contemporary vehicles often incorporate various independent control systems sourced from numerous vendors—each managed by separate development groups with differing objectives—it’s clear why many recent models lack distinct driving personalities.

BMW aims to shift this paradigm with their new initiative called "Heart of Joy." This rather oddly titled compartment is designed to house and manage all functionalities. The company envisions its upcoming vehicles as more than just excellent driving tools; they aspire for these cars to provide distinctly different and unforgettable driving adventures. To achieve uniqueness, BMW has introduced Heart of Joy, which is intended to facilitate this vision.

At the recent IAA exhibition in Munich, we had an opportunity to engage in a comprehensive discussion with Nicolai Martin, BMW’s Senior Vice President of Driving Experience. This conversation delved into what drives innovation within their tech-centric environment and explored how these changes will transform the fundamental processes involved in developing new vehicles.

The Concept

If you read our in-car Ethernet explainer , you know that modern cars are made up of many different computing systems scattered throughout the chassis. Yes, there's usually a central electronic control unit (ECU) that keeps everything in check, but there could be dozens of other subprocessors around, all connected by increasingly high-bandwidth systems to pass data back and forth.

So while the main ECU is calling the shots, it might defer to another computer to handle the stability control, passing the buck to still another one to handle ABS activation in slippery conditions, with more discrete processors controlling everything from automatic wipers to blind-spot monitoring.

As often as not, these separate processors and the code they run are provided wholesale by suppliers. The appeal is that they're largely plug-and-play. A manufacturer can quickly add advanced stability or driver assistance systems without having to dedicate a lot of time and money to figure out how all that should behave.

The positive aspect is clear. However, the downside is that vehicles utilizing these systems will essentially operate similarly. Consider how many vehicle manufacturers use gearboxes supplied by ZF or anti-lock braking systems provided by Bosch. Indeed, each company applies their specific adjustments and validation processes; nonetheless, significant alterations become limited when full access across all aspects of the vehicle isn’t available.

BMW's Heart of Joy removes all these separate roles within the workforce. This unified central system manages almost every facet of the vehicle. The entire suite of software is crafted internally at BMW according to their specific requirements. By cutting out intermediary steps with external suppliers and opening up access across systems, BMW’s engineering team has full command over the overall experience.

Heart of Joy's Benefits

When we sought an illustration from BMW’s Martin regarding how this plays out practically, he initially pointed to the aspect of braking. It turns out that ABS (Anti-lock Braking System) is something many manufacturers frequently delegate to external suppliers. These suppliers provide fully functional and reliable antilock braking mechanisms ready to be installed directly onto vehicles with minimal additional effort required.

But as BMW begins to transistion onto its all-new, dedicated Neue Klasse EV platform , situations are becoming more intricate. Regenerative braking could soon have a significantly greater role in halting a vehicle. Through Heart of Joy, Martin indicates that BMW may enable the car to come to a full stop without depending on traditional brake systems at all.

He mentioned that it minimizes the noise," which is crucial in an electric vehicle designed for silence. However, there are also performance considerations: "In regular driving conditions, you can use more advanced regenerative braking modes, as long as you manage the sensor feedback correctly, particularly when driving on wet roads.

Through direct interaction with the wheel speed sensors and the brake system itself, BMW’s Heart of Joy will facilitate the accuracy required for smooth regenerative braking in conditions where traction is limited. This principle applies across every aspect of the vehicle, from stability control and traction management to interior amenities. Additionally, since everything operates via software, future enhancements can be readily implemented through updates.

"Nearly all of our electronic components in the vehicle, about 99 percent, can be updated remotely," Martin stated, noting that this encompasses elements such as window-raising mechanisms. Enhanced safety protocols and update procedures will allow BMW to securely refresh the whole car’s software within under 20 minutes.

This indicates that BMW has the capability to swiftly introduce fresh software into vehicles even as they test and develop prototype automobiles. As mentioned, “we have the ability to create software every hour,” he stated, adding, “when we’re out at the racetrack, our pace of advancement mirrors that of a racing crew.”

The Hardware

Apart from offering straightforward integration, pre-made systems address a key problem that has constrained their capacity to manage every aspect efficiently: bus latency. When several processors within the computer handle various components of the driving experience, they require time to share data across the vehicle’s communication system, known as a bus.

Martin stated that "All systems involving buses between Electronic Control Units must manage at least 10 milliseconds, 20 milliseconds." This delay might seem quick for someone playing games, but it isn’t sufficient for vehicles operating in reality. However, by removing these intermediaries, Heart of Joy aims to achieve a latency below 1 millisecond, according to Martin.

So we are now at least ten times quicker. This allows us to elevate regeneration capabilities, handling characteristics, and everything else to an entirely new level. Additionally, the entire software structure and feature design have been revamped.

Martin indicated that most of the data transfer is managed via Ethernet, while Infineon’s chips take care of the specific networking tasks.

The People

While the behavior of the car might be determined by its hardware and software, you shouldn’t assume this will render everything impersonal and mechanical. A key objective is to streamline things so that BMW’s proficient experts in hardware, software, and development can more easily achieve their desired outcomes with the vehicle.

That's an undertaking involving many individuals. According to Martin, approximately 2,000 engineers are addressing aspects such as driving dynamics and automated driving. Among them, around 600 are dedicated software developers.

BMW is also increasingly conducting its vehicle tests through digital means by utilizing simulations. He mentioned, "We've equipped an entirely new facility with top-of-the-line simulation tools." It feels as though one needs to prepare for a future space mission just to operate them.

Martin indicated that BMW is taking virtual testing of tire compounds to an extreme level. The capabilities of this advanced system are robust enough to tackle one significant gap in simulation-based driving tests—tire flexibility—which had previously posed challenges.

In earlier simulators, both the virtual chassis and tires were entirely inflexible. Even though the suspension could operate as intended, the different parts of the structure wouldn’t interact realistically. However, thanks to recent advancements in computational capabilities, every component can now bend accordingly. He mentioned that his team has had this capability for just a short time. “Currently, our simulator manages all these physical interactions seamlessly,” he stated, expressing his own amazement at how authentic it feels. Riding it multiple times has convinced him that the car’s behavior seems incredibly lifelike.

The Philosophy

Martin stated that BMW’s approach stands out as entirely distinct. "Up until now, we are the sole original equipment manufacturer integrating the software and the ECU for managing both the powertrain and plug-ins so cohesively. This allows us, among other things, to provide enhanced driving dynamics and superior enjoyment during high-performance drives."

BMW appears to be pushing these boundaries further than ever before; however, comparable ideas have emerged in previous car models. A close analogy could be drawn with Tesla, which has gradually eliminated various external components sourced from different suppliers, opting instead to develop custom-built software for much of their vehicle’s internal operations. According to Tesla, this approach was pivotal in achieving significant advancements once the Model 3 Performance hit the market back in 2018.

BMW aims not just to elevate the standards of automotive performance, but also to reshape the experience of driving a BMW, infusing significant personality into vehicles driven purely by lines of coding. They strive to guarantee that all components function together seamlessly.

The News Pulse

Post a Comment for "Unlocking BMW's 'Joy Factor': How Software Will Revolutionize the Driving Experience"

Post a Comment